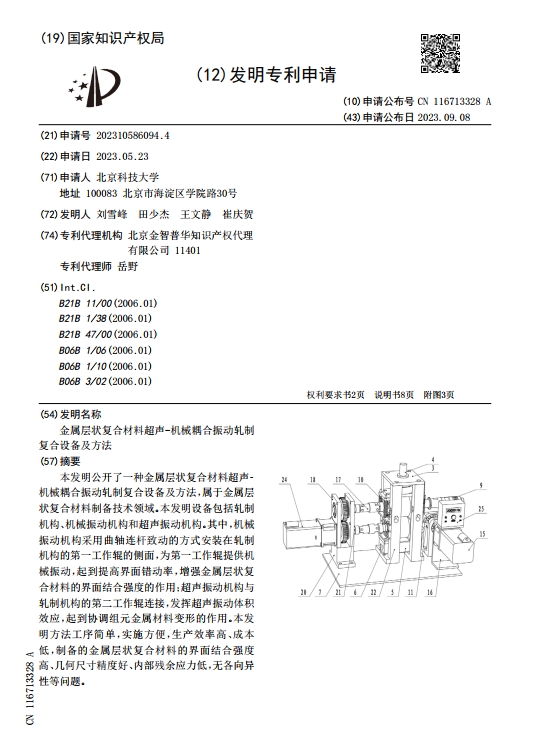

本发明公开了一种金属层状复合材料超声‑机械耦合振动轧制复合设备及方法,属于金属层状复合材料制备技术领域。本发明设备包括轧制机构、机械振动机构和超声振动机构。其中,机械振动机构采用曲轴连杆致动的方式安装在轧制机构的第一工作辊的侧面,为第一工作辊提供机械振动,起到提高界面错动率,增强金属层状复合材料的界面结合强度的作用;超声振动机构与轧制机构的第二工作辊连接,发挥超声振动体积效应,起到协调组元金属材料变形的作用。本发明方法工序简单,实施方便,生产效率高、成本低,制备的金属层状复合材料的界面结合强度高、几何尺寸精度好、内部残余应力低,无各向异性等问题。

The present invention discloses an ultrasonic-mechanical coupled vibration rolling composite equipment and method for metal laminated composite materials, which belongs to the technical field of metal laminated composite material preparation. The equipment of the present invention includes a rolling mechanism, a mechanical vibration mechanism and an ultrasonic vibration mechanism. Among them, the mechanical vibration mechanism adopts a crankshaft linkage actuation mounted on the side of the first work roll of the rolling mechanism to provide mechanical vibration for the first work roll, which plays a role in improving the interfacial misalignment rate and enhancing the interfacial bonding strength of the metal layered composite material; the ultrasonic vibration mechanism is connected with the second work roll of the rolling mechanism to play the role of the ultrasonic vibration volume effect and play a role in coordinating the deformation of the component metal materials. The method of the present invention is simple in process, convenient in implementation, high in productivity and low in cost, and the prepared metal laminated composite material has high interfacial bonding strength, good geometrical dimensional accuracy, low internal residual stress, and no anisotropy.