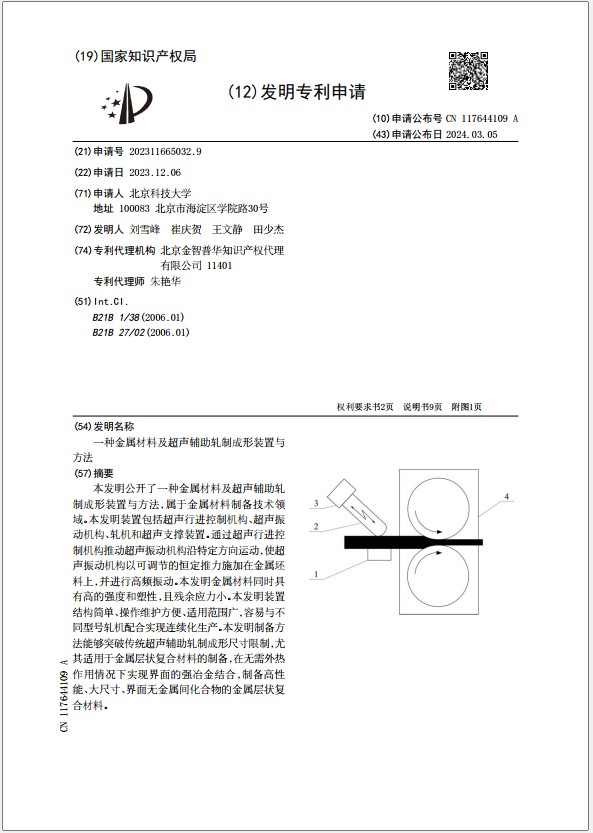

本发明公开了一种金属材料及超声辅助轧制成形装置与方法, 属于金属材料制备技术领域。本发明装置包括超声行进控制机构、超声振动机构、轧机和超声支撑装置。 通过超声行进控制机构推动超声振动机构沿特定方向运动, 使超声振动机构以可调节的恒定推力施加在金属坯料上, 并进行高频振动。本发明金属材料同时具有高的强度和塑性, 且残余应力小。本发明装置结构简单、操作维护方便、适用范围广, 容易与不同型号轧机配合实现连续化生产。本发明制备方法能够突破传统超声辅助轧制成形尺寸限制, 尤其适用于金属层状复合材料的制备, 在无需外热作用情况下实现界面的强冶金结合, 制备高性能、大尺寸、界面无金属间化合物的金属层状复合材料。

The present invention discloses a metal material and ultrasound-assisted roll forming device and method, belonging to the technical field of metal material preparation. The device of the present invention includes an ultrasonic traveling control mechanism, an ultrasonic vibration mechanism, a rolling mill and an ultrasonic support device. The ultrasonic vibration mechanism is driven by the ultrasonic travel control mechanism in a specific direction, so that the ultrasonic vibration mechanism is applied to the metal blank with an adjustable constant thrust, and high-frequency vibration. The metal material of the present invention has both high strength and plasticity with low residual stress. The invention device structure is simple, easy to operate and maintain, applicable to a wide range, easy to cooperate with different types of rolling mills to achieve continuous production. The preparation method of the present invention can break through the traditional ultrasound-assisted rolling and forming size limitations, especially for the preparation of metal laminated composite materials, without external heat to achieve strong metallurgical bonding of the interface, to prepare high-performance, large-size metal laminated composite materials without intermetallic compounds at the interface.