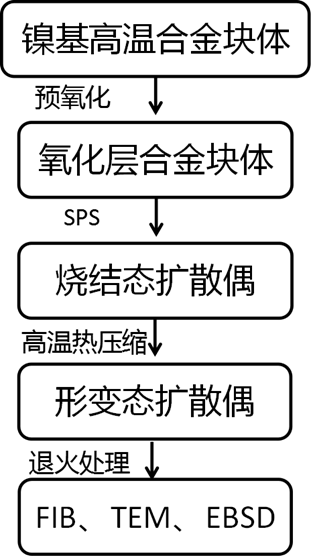

数据集内容:发明了一种基于中断烧结的粉末高温合金中氧化物溶解扩散行为的研究方法,包括:(1)将高温合金粉末在真空气氛中进行短时烧结得到烧结体;(2)将烧结体进行退火处理得到退火样品;(3)采用超薄切片的方法,将高温合金粉末切取合金粉末表层,并结合TEM分析杂质氧的分布规律;(4)采用FIB,分别将烧结体和退火样品切取烧结颈,分析合金粉末表层的杂质氧进入退火样品内部后的存在形式及扩散规律。本发明所述方法可批量制备出不同烧结阶段的近终成型坯体,通过调节退火时间及施加的压力影响块体的致密度,以模拟保温时间及压力对氧化物溶解扩散行为的影响。为研究热等静压过程中高温合金粉末表面氧化物的溶解扩散行为提供原材料。

Data set content: A method for studying the dissolution and diffusion behavior of oxides in powder superalloys based on interrupted sintering is developed, which includes: (1) the superalloy powder is sintered in a vacuum atmosphere for a short time to obtain the sintered body; (2) The sintered body is annealed to obtain the annealed sample; (3) The superalloy powder surface was cut by ultra-thin slice method, and the distribution of impurity oxygen was analyzed by TEM. (4) Using FIB, the sintered body and annealed sample were cut into the sintering neck respectively, and the existence form and diffusion rule of the impurity oxygen on the surface of the alloy powder were analyzed after entering the annealed sample. The method of the invention can batch prepare near-final forming billets at different sintering stages, and influence the density of the blocks by adjusting the annealing time and applied pressure, so as to simulate the influence of holding time and pressure on the dissolution and diffusion behavior of oxides. It provides raw materials for studying the dissolution and diffusion behavior of superalloy powders during hot isostatic pressing.